Mobile No.

+91 97663 36366

Test Pressure in bar (psi) |

||||

Pressure rating 2) |

Class 150 |

Class 300 |

PN 10 |

PN 16 |

Hyd. Shell |

30 (435) |

76 (1102) |

15 (218) |

24.0 (348) |

| Seat | 22 (319) |

55 (798) |

11 (160) |

17.6 (255) |

| Air Seat | 6.9 (100) |

|||

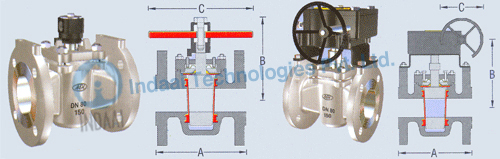

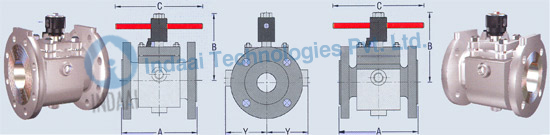

| Dimensions are in mm (inch) | ||||||||||||||||||||||

SIZE mm/inch |

|

B |

C |

PORT AREA mm2/inch2 |

% PORT OPEN |

|

||||||||||||||||

15 /.5 |

108/4.3 |

140/5.5 |

130/5.1. |

95/3.7 |

225/8.9 |

120/.19 |

92 |

2.0/4.5 |

3.5/8 |

2.6/6 |

||||||||||||

20/.75 |

117/4.6 |

152/6.0 |

150/5.9 |

100/3.9 |

225/8.9 |

240/.37 |

86 |

2.5/5.5 |

5.0/11 |

3.5/8 |

||||||||||||

25/1 |

127/5.0 |

165/6.5 |

160/6.3 |

110/4.3 |

225/8.9 |

390/.6 |

80 |

4.5/10 |

6.5/14 |

5.7/13 |

||||||||||||

40/1.5 |

165/6.5 |

190/7.5 |

22/7.9 |

120/4.7 |

325/12.8 |

750/1.16 |

66 |

7.5/17 |

11/24 |

9.6/21 |

||||||||||||

50/2.0 |

178/7.0 |

216/8.5 |

230/9.1 |

145/5.7 |

450/17.7 |

1450/2.25 |

74 |

12/27 |

16/35 |

15/33 |

||||||||||||

65/2.5 |

190/7.5 |

241/9.5 |

290/11.4 |

175/6.9 |

600/23.6 |

2080/3.22 |

66 |

15/33 |

19/42 |

22/49 |

||||||||||||

80/3.0 |

203/8.0 |

283/11.1 |

310/12.2 |

160/6.3 |

450/17.7 |

2540/3.94 |

53 |

18/40 |

22/49 |

24/53 |

||||||||||||

100/4.0 |

229/9.0 |

305/12.0 |

350/13.8 |

195/7.7 |

750/29.5 |

4470/6.93 |

57 |

30/66 |

44/97 |

38/84 |

||||||||||||

150/6.0 |

267/10.5 |

403/15.9 |

480/18.9 |

250/9.8 |

400/15.7 |

10010/15.52 |

55 |

65/143 |

96/212 |

90/198 |

||||||||||||

200/8.0 |

292/11.5 |

419/16.5 |

600/23.6 |

280/11.0 |

450/17.7 |

15800/24.50 |

49 |

106/234 |

151/333 |

166/366 |

||||||||||||

250/10.0 |

330/13.0 |

457/18.0 |

730/28.7 |

340/13.4 |

600/23.6 |

23820/36.92 |

47 |

160/353 |

225/496 |

270/595 |

||||||||||||

300/12.0 |

356/14.0 |

502/19.8 |

850/33.5 |

390/15.4 |

700/27.6 |

31220/48.4 |

43 |

210/463 |

280/617 |

395/870 |

||||||||||||

350/14.0 |

381/15.0 |

450/17.7 |

700/27.6 |

38180/59.18 |

43 |

310/683 |

||||||||||||||||

400/16.0 |

762/30.0 |

595/23.4 |

500/19.7 |

74458/115.41 |

61 |

650/1433 |

||||||||||||||||

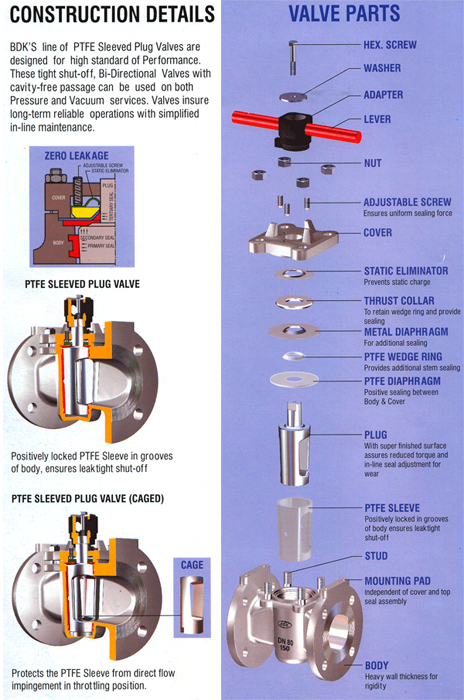

Materials |

|

Body & cover 3) |

Ductile Iron, ASTM A395 Steel / ASTM A216 Gr.WCB / ASTM A351 Gr. CF8 / CF8M / CN7M |

Plug |

Steel ASTM A 217 Gr. CA15 / ASTM A 351 Gr. CF8 / CF8M / CN7M |

Sleeve / Diaphragm |

PTFE / CFT |

Wedge Ring |

PTFE / Grafoil 5) |

Metal Diaphragm |

ASTM A 240 Type 304 |

Thrust collar & adj Screw |

ASTM A276 Type 304 / ASTM A351 Gr.CF8 |

Static eliminator |

ASTM A240 Type 304 |

Studs / Nuts |

ASTM A 193 Gr. B8 / ASTM A 194 Gr.8 |

Adaptor / Lever |

Steel - Powder coated |

Gear Unit |

Housing in Cast Iron, Gear in S.G.Iron & worm in EN8 |

Bearing-4) |

PTFE |

Body Gasket 5) |

Grafoil |

Surface protection for Ductile Iron & Cast Carbon Steel Valves |

Prime coat :Chlorine free with modified alkyd resin unobjectionable in physiological & toxicological respects. Additional external coating: Synthetic enamel. |

1) Nett in Kg (Ibs.) approx. (without obligation) 2) Pressure rating: PN1 0, PN16 & Class 150 for DIN Valves. 3) DI material for Class 150 only. 4) For Caged Valves only. 5) For Fire safe Valves only. * Gear Actuators mandatory for Sizes 150 (6") & above. * Valves can be supplied to suit ASME B 16.5.Other Drillings on requests if possible. * Face to Face dimensions (A) as per EN 558 - 2 Series 3 for Class 150 Sizes up to 350(14"), Series 12 for Size 400 (16"), Series 4 for Class 300, Series 1 for DIN Valves. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Pad - lock, Electric, Pneumatic or Gear Actuators * Other Materials not mentioned above available on requests.

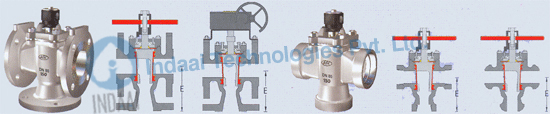

SIZE mm / inch |

|

B |

C |

|

||||||||||

15 / .5 |

83/3.3 |

250/9.8 |

95/3.7 |

225/8.9 |

1.7/3.5 |

2.0/4.5 |

||||||||

20/0.75 |

83/3.3 |

250/9.8 |

100/3.9 |

225/8.9 |

1.9/4.0 |

2.3/5.0 |

||||||||

25.0/1.0 |

117/4.6 |

280/11.0 |

110/4.3 |

225/8.9 |

3.5/8.0 |

4.0/9.0 |

||||||||

40/1.5 |

140/5.5 |

330/13.0 |

120/4.7 |

325/12.8 |

4.5/10.0 |

5.0/11.0 |

||||||||

50/2.0 |

165/6.5 |

360/14.2 |

145/5.7 |

450/17.7 |

7.5/17.0 |

8.0/18.0 |

||||||||

65/2.5 |

190/7.5 |

400/15.7 |

175/6.9 |

600/23.6 |

9.5/21.0 |

9.5/21.0 |

||||||||

80/3.0 |

203/8.0 |

425/16.7 |

160/6.3 |

450/17.7 |

11.0/24.0 |

12.0/27.0 |

||||||||

Materials |

|

Body & Cover |

Ductile IronASTM A 395 / Steel ASTM A 216 Gr. WCB / ASTM A 351 Gr. CF8 / CF8M / CN7M |

Plug |

Steel ASTM A 217 Gr. CA15 / ASTM A 351 Gr.CF8 / CF8M / CN7M |

Sleeve/ Diaphragm |

PTFE / CFT |

Wedge Ring |

PTFE / Grafoil |

Metal diaphragm |

ASTM A 240 Type 304 |

Thrust Collar & Adj. screw |

ASTM A 276 Type 304 |

Static Eliminator |

ASTM A 240 Type 304 |

Studs & Nuts |

ASTM A 193 Gr. B8 / ASTM A 194 Gr. 8 |

Adapto / Lever |

Steel Powder coated |

Bearing-3 |

PTFE |

Body Gasket |

Grafoil |

Surface Protection for ductile iron & cast carbon Steel Valves |

Prime coat : Chlorine free with modified alkyd rsin unobjectionable in physiological &toxicological respects.Additional External Coating:Synthetic Enamel |

1) Nett in Kg. (lbs.) approx. (without obligation) 2) DI material for Class 150 & Screwed ends only. 3) For Caged Valves only. 4) For Fire safe Valves only. * Standard Screwed ends to have BS: 21 (Parallel or Taper) or ANSI/ ASME B 1. 20.1 (NPT)threads. Socket Weld ends as per ASME B 16.11 & Butt weld ends as perASME B 16.25 suitable for schedule 40 /40S. * Please Specify Working Pressure, Temperature & Service conditions.* Valves can be supplied with Pad - lock, Electric, Pneumatic or Gear Actuators. * Other Materials not mentioned above available on requests.

| SIZE mm / inch |

|

|

||||||||||

15 (1/2) |

70 (2.8) |

73 (2.9) |

3.0 (7) |

5.0 (11) |

||||||||

20 (3/4) |

73 (2.9) |

76 (3.0) |

3.5 (8) |

7.5 (17) |

||||||||

25 (1) |

89 (3.5) |

95 (3.7) |

5.5 (12) |

9.0 (20) |

||||||||

40(1 1/2) |

105 (4.1) |

110 (4.3) |

9.5 (21) |

15.5 (34) |

||||||||

50 (2) |

114 (4.5) |

120 (4.7) |

15.0 (33) |

21.5 (47) |

||||||||

65(2 1/2) |

130 (5.1) |

140 (5.5) |

18.0 (40) |

25.0 (55) |

||||||||

80 (3) |

130 (5.1) |

140 (5.5) |

23.5 (52) |

32.0 (71) |

||||||||

100 (4) |

152 (6.0) |

170 (6.7) |

40.0 (88) |

60.0 (132) |

||||||||

150 (6) |

190 (7.5) |

216 (8.5) |

70.0 (154) |

115 (254) |

||||||||

200 (8) |

230 (9.1) |

255 (10.0) |

115 (254) |

182 (401) |

||||||||

250 (10) |

280 (11.0) |

310 (12.2) |

172 (379) |

260 (573) |

||||||||

300 (12) |

320 (12.6) |

380 (15.0) |

240 (529) |

285 (628) |

||||||||

350 (14) |

445 (17.5) |

360 (794) |

||||||||||

400 (16) |

530 (20.9) |

715 (1575) |

||||||||||

|

|

||||

43 (1.7) |

2.5 (6) |

||||

57 (2.2) |

3.0 (7) |

||||

60 (2.4) |

4.2 (9) |

||||

73 (2.9) |

5.3 (12) |

||||

86 (3.4) |

8.5 (19) |

||||

95 (3.7) |

10.5 (23) |

||||

105 (4.1) |

12.0 (27) |

1) Nett in Kg. (Ibs.) Approx. (without obligation) . Standard Screwed ends to have BS : 21 ( Parallel or Taper) or ANSI / ASME B 1. 20.1 ( NPT) threads. Socket Weld ends as per ASME B 16.11 & Butt weld ends as per ASME B 16.25 suitable for schedule 40 /40S. * Gear Actuators mandatory for Sizes 150 (6") & above. * Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied with Pad - lock, Electric, Pneumatic or Gear Actuators. * For other Dimensions refer previous page.

Dimension are in mm (inch) |

|||||||||||||||||||||||||||

FULLY PARTIALLY JACKETING |

|||||||||||||||||||||||||||

PARTIALLY JACKETING |

FULLY JACKETING | CLASS - 150 & 300 |

|||||||||||||||||||||||||

size mm(inch) |

FLANGE SIZE |

|

C |

Y |

|

|

|

||||||||||||||||||||

15 (112) |

25 (1) |

108 (4.3) |

140 (5.5) |

225 (8.9) |

35 |

2.0 |

3.5 |

3.0 |

6.5 |

95 |

125 (4.9) |

||||||||||||||||

20 (3'4) |

40 (1112) |

117 (4.6) |

152 (6.0) |

225 (8.9) |

40 |

2.5 |

5.0 |

4.5 |

8.0 |

100 (3.9) |

130 (5.1) |

||||||||||||||||

25 (1) |

50 (2) |

127 (5.0) |

165 (6.5) |

225 (8.9) |

45 |

4.5 |

6.5 |

7.5 |

10.5 |

110 (4.3) |

142 (5.6) |

||||||||||||||||

40 (1112) |

65 (2 112) |

165 (6.5) |

190 (7.5) |

325 (12.8) |

50 |

7.5 |

11.0 |

10.0 |

16.0 |

120 (4.7) |

148 (5.8) |

||||||||||||||||

50 (2) |

80 (3) |

178 (7.0) |

216 (8.5) |

450 (17.7) |

60 |

12.0 |

16.0 |

15.0 |

20.0 |

145 (5.7) |

175 (6.9) |

||||||||||||||||

65 (2 1/2) |

100 (4) |

190 (7.5) |

241 (9.5) |

600 (23.6) |

70 (2.8) |

15.0 (33) |

19.0 (42) |

22.0 (49) |

25.0 (55) |

175 (6.9) |

208 (8.2) |

||||||||||||||||

80 |

100 |

203 (8.0) |

283 (11.1) |

450 (17.7) |

70 |

18.0 |

22.0 |

24.0 |

30.0 |

160 (6.3) |

188 (7.4) |

||||||||||||||||

100 |

150 |

229 (9.0) |

305 (12.0) |

750 (29.5) |

80 |

30.0 |

44.0 |

37.0 |

54.0 (119) |

195 (7.7) |

235 (9.3) |

||||||||||||||||

150 |

200 |

267 (10.5) |

403 (15.9) |

* |

115 (4.5) |

60.0 |

91.0 |

80.0 (176) |

115.0 (254) |

250 (9.8) |

250 (9.8) |

||||||||||||||||

200 |

250 |

292 (11.5) |

419 (16.5) |

* |

130 (5.1) |

96.0 (211) |

148.0 (326) |

125.0 (276) |

170.0 (375) |

280 (11.0) |

280 (11.0) |

||||||||||||||||

250 |

300 |

330 (13.0) |

457 (18.0) |

* |

145 |

142.0 (313) |

210.0 (463) |

160.0 (353) |

260.0 (573) |

340 (13.4) |

340 (13.4) |

||||||||||||||||

300 |

350 |

356 (14.0) |

502 (19.8) |

* |

150 |

195.0 (430) |

- |

230.0 (507) |

390 (15.4) |

390 (15.4) |

|||||||||||||||||

350 |

400 |

381 (15.0) |

- |

* |

165 (6.5) |

325.0 (717) |

- |

330.0 (728) |

450 (17.7) |

450 (17.7) |

|||||||||||||||||

400 |

500 |

762 (30.0) |

- |

* |

265 (10.4) |

670.0 (1477) |

650.0 (1433) |

595 (23.4) |

595 (23.4) |

||||||||||||||||||

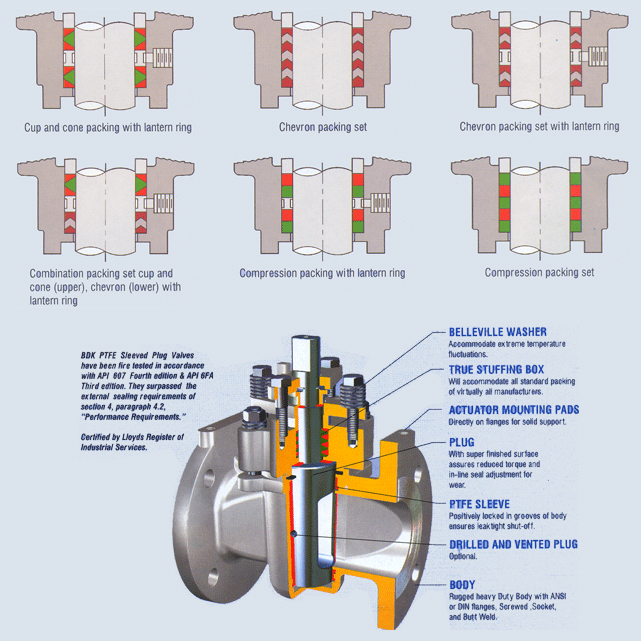

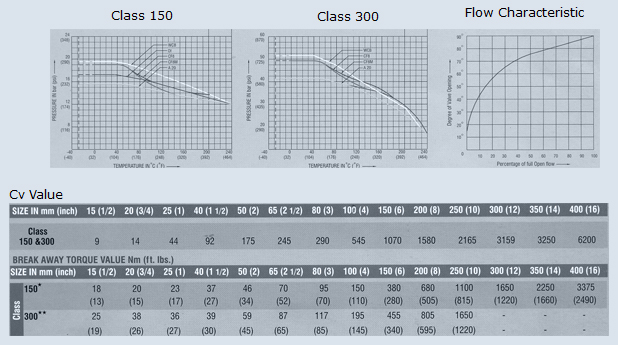

| Actuator Selection | ||||||

| Multiply the above Torque values by following factors ' F ' to get the Actuator Torque. | ||||||

SERVICE |

Raw Water |

Wet Services |

Steam |

Gas |

Slurry |

Viscous Liquid |

FECTOR 'F' |

1.35 |

1.35 |

1.25 |

1.40 |

1.80 |

2.0 |