Mobile No.

+91 97663 36366

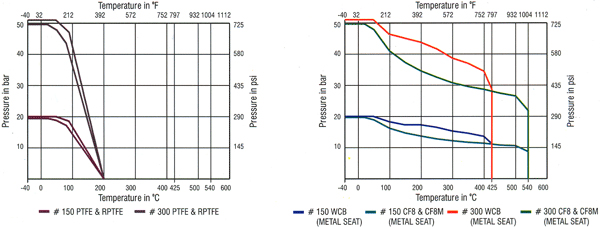

Test Pressure in bar (psi) |

|

Class |

150 |

Hyd. Shell |

30 (435) |

Seat |

223(319) |

Air Seat |

6.9 (100) |

Test Pressure in bar (psi) |

|

Class |

300 |

Hyd. Shell |

76 (1102) |

Seat |

55(798) |

Air Seat |

6.9 (100) |

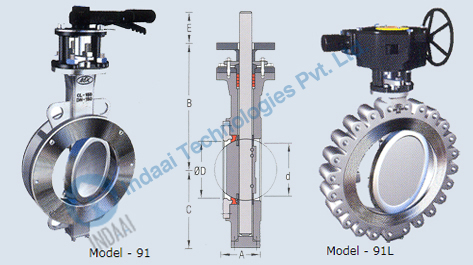

Dimensions are in mm (inch) |

Class 150, 91 & 91L |

|||||||||||

SIZE |

A |

B |

C |

D |

d3) |

E |

|

|||||

50 (2) |

43 (1.7) |

164 (6.5) |

93 (3.7) |

62 (2.4) |

41 (1.6) |

29 (1.1) |

5.5 (12) |

7.5 (17) |

||||

65 (21/2) |

46 (1.6) |

181 (7.1) |

99 (3.9) |

75 (3.0) |

52 (2) |

29 (1.1) |

6 (13) |

8 (18) |

||||

80 (3) |

48 (1.9) |

208 (8.2) |

120(4.7) |

92 (3.6) |

60 (2.4) |

29 (1.1) |

8 (18) |

10 (22) |

||||

100 (4) |

54 (2.1) |

234 (9.2) |

135 (5.3) |

114 (4.5) |

80 (3.1) |

30 (1.2) |

11 (24) |

14 (31) |

||||

125 (5) |

57 (2.2) |

238 (9.4) |

142 (5.6) |

134 (5.3) |

111 (4.4) |

30 (1.2) |

12 (26) |

14 (31) |

||||

150 (6) |

57 (2.2) |

254 (10) |

175 (6.9) |

158 (6.2) |

135 (5.3) |

30 (1.2) |

16 (35) |

20 (44) |

||||

200 (8) |

64 (2.4) |

305 (12) |

185 (7.3) |

214 (8.4) |

180 (7.1) |

60 (2.4) |

36 (79) |

45 (99) |

||||

250 (10) |

71 (2.8) |

340 (13.4) |

225 (8.9) |

260 (10.2) |

225 (8.9) |

75 (3) |

55 (121) |

62 (137) |

||||

300 (12) |

81 (3.2) |

380 (15) |

265 (10.4) |

314 (12.4) |

285 (11.2) |

85 (3.3) |

70 (154) |

84 (185) |

||||

350 (14) |

92 (3.6) |

415 (16.3) |

300 (11.8) |

354 (13.9) |

310 (12.2) |

85 (3.3) |

70 (154) |

84 (185) |

||||

400 (16) |

102 (4) |

445 (17.5) |

325 (12.8) |

399 (15.7) |

356 (14) |

120 (4.7) |

140 (309) |

204 (450) |

||||

450 (18) |

115 (4.5) |

505 (19.9) |

355 (14) |

454 (17.9) |

406 (16) |

90 (3.5) |

180 (397) |

360 (794) |

||||

500 (20) |

128 (5) |

545 (21.5) |

380 (15) |

494 (19.4) |

454 (17.9) |

135 (5.3) |

230 (507) |

456 (1005) |

||||

600 (24) |

154 (6.1) |

640 (25.2) |

450 (17.7) |

584 (23) |

538 (21.2) |

125 (4.9) |

350 (772) |

552 (1217) |

||||

| Dimensions are in mm (inch) | Class 300,91L |

||||||

SIZE- mm /inch |

A |

B |

C |

D |

d3 |

E |

Wt1) |

50 /2 |

43 /1.7 |

164 /6.5 |

93 /3.7 |

62 /2.4 |

41 /1.6 |

29 /1.1 |

9 /20 |

65/ 21/2 |

46 /1.8 |

181 /7.1 |

99 /3.9 |

75 /3.0 |

52 /2.0 |

29 /1.1 |

11/24 |

80 /3.0 |

48 /1.9 |

208 /8.2 |

120 /4.7 |

92 /3.6 |

60 /2.4 |

29 /1.1 |

13 /29 |

100 /4.0 |

54 /2.1 |

234 /9.2 |

135 /5.3 |

114 /4.5 |

80 /3.1 |

30 /1.2 |

18 /40 |

125 /5 |

57 /2.2 |

274 /10.8 |

142 /5.6 |

134 /5.3 |

111 /4.4 |

30 /1.2 |

24 /53 |

150 /6 |

59 /2.3 |

290 /11.4 |

175 /6.9 |

158 /6.2 |

135 /5.3 |

65 /2.6 |

40 /88 |

200 /8 |

73 /2.9 |

335 /13.2 |

210 /8.4 |

214 /8.4 |

180 /7.1 |

75 /3.0 |

60 /132 |

250 /10 |

83 /3.3 |

370 /14.6 |

240 /9.4 |

264 /10.4 |

220 /8.7 |

85 /3.3 |

95 /209 |

300 /12 |

92 /3.6 |

445 /17.5 |

285 /11.2 |

314 /12.4 |

285 /11.2 |

90 /3.5 |

130 /287 |

350 /14 |

117 /4.6 |

480 /18.9 |

315 /12.4 |

354 /13.9 |

302 /11.9 |

90 /3.5 |

180 /397 |

400 /16 |

133 /5.2 |

510 /20.1 |

355 /14.0 |

399 /15.7 |

350 /13.8 |

140 /5.5 |

315 /694 |

450 /18 |

149 /5.9 |

550 /21.7 |

385 /15.2 |

454 /17.9 |

396 /15.6 |

120 /4.7 |

390 /860 |

500 /20 |

159 /6.3 |

610 /24.0 |

420 /16.5 |

494 /19.4 |

441 /17.4 |

150 /5.9 |

550 /1213 |

600 /24 |

181 /7.1 |

690 /27.2 |

490 /19.3 |

584 /23.0 |

526 /20.7 |

150 /5.9 |

725 /1598 |

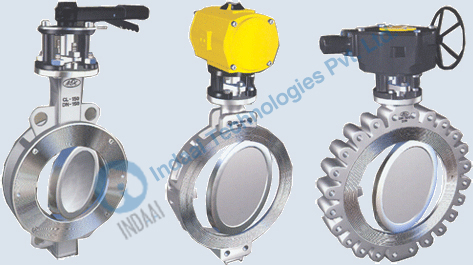

Materials |

|

Body |

Steel ASTM A216 Gr.WCB / Stainless SteelASTM A351 Gr. CF8 / CF8M / CN7M |

Disc |

Stainless Steel ASTM A351 Gr. CF8 / CF8M / CN7M |

Seat |

PTFE / RPTFE / ASTM A240 TYPE 316 / INCONEL |

Stem |

Steel ASTM A276 TYPE 410 / 304 / 316 / A-20 |

Stem Bearings |

PTFE / RPTFE / ASTM A439 TYPE D2 Ni-Resist |

Handle Unit 4) |

Carbon Steel / S.G. Iron |

Gear Unit 4) |

Gear in S.G.Iron / EN8 and Worm in EN19 |

Surface Protection for Cast Carbon Steel Valves |

Prime coat : Chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects. Additional exernal coating : Heat resistant silver streak asluminium paint. |

| Cv Values (Full Open) | ||

| SIZE | CLASS150 | CLASS 300 |

| 50 / 2 | 100 | 100 |

| 65 / 2.5 | 150 | 150 |

| 80 / 3 | 242 | 242 |

| 100 / 4 | 488 | 488 |

| 125 / 5 | 740 | 740 |

| 150 / 6 | 1260 | 1260 |

| 200 / 8 | 200 | 2200 |

| 250 / 10 | 3420 | 3200 |

| 300 / 12 | 5100 | 4500 |

| 350 / 14 | 6300 | 5800 |

| 400 / 16 | 8200 | 7200 |

| 450 / 18 | 10500 | 9500 |

| 500 / 20 | 14000 | 12700 |

| 500 / 20 | 14000 | 12700 |

| 600 / 24 | 21600 | 19500 |

| TORQUE VALUES Nm(ft.lbs) 100% P | |||

| PTFE SEAL | METAL TO METAL & FIRE SAFE VALVES | ||

| CLASS150 | CLASS300 | CLASS150 | CLASS300 |

| 35 / 26 | 68 / 50 | 78 / 58 | 110 / 81 |

| 40 / 30 | 80 / 59 | 88 / 65 | 160 / 118 |

| 49 / 36 | 89 / 66 | 93 / 69 | 177 / 131 |

| 69 / 51 | 128 / 95 | 133 / 98 | 245 / 181 |

| 103 / 76 | 195 / 144 | 133 / 98 | 245 / 181 |

| 157 / 116 | 295 / 218 | 241 / 178 | 442 / 326 |

| 314 / 232 | 569 / 420 | 452 / 334 | 824 / 608 |

| 451 / 333 | 814 / 601 | 618 / 456 | 1128 / 833 |

| 628 / 464 | 1138 / 840 | 1236 / 912 | 2237 / 1651 |

| 1207 / 891 | 2178 / 1607 | 1540 / 1137 | 2796 / 2064 |

| 1570 / 1159 | 2845 / 2100 | 1933 / 1427 | 3532 / 2607 |

| 2100 / 1550 | 3826 / 2824 | 3002 / 2216 | 5445 / 4018 |

| 2698 / 1991 | 4905 / 3620 | 3728 / 2751 | 6769 / 4996 |

| 3924 / 2896 | 7358 / 5430 | 5935 / 4380 | 10791 / 7964 |

1) Nett in Kg.(lbs.) approx. (without obligation) 2) Grade according to Working Pressure, Temperature & Service conditions. 3) Internal diameter of pipe should be atleast 3mm (0.1") (For Sizes 50 (2") - 300 (12") and 6 mm (0.2") (for Sizes 350 (14") - 500 (20") and 13 mm (0.5") (for Size 600 (24") more than 'd' 4) Gear Actuators mandatory for Sizes 200 (8") & above in Class 150 Valves & for Sizes 150 (6") & above in Class 300 Valves.* Please Specify Working Pressure, Temperature & Service conditions. * Valves can be supplied to suit ASME / BS / DIN Flanges.* Fire safe Valves incorporates primary PTFE & secondary Metal Seat & Ni-Resist Steel Stem bearing.* For Fire safe Services only Model 91 L is recommended. * Other Materials not mentioned above available on request.

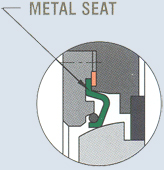

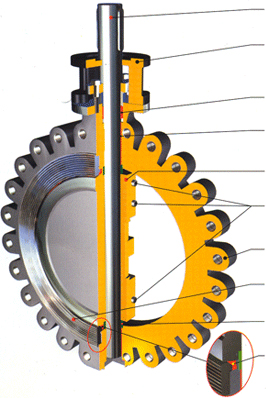

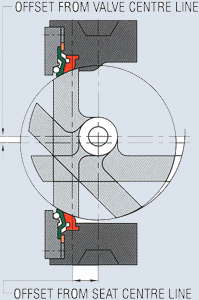

DOUBLE OFFSET |

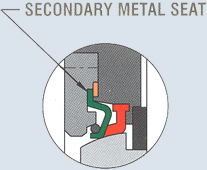

FIRE SAFE |

HIGH TEMPERATURE SERVICES |

|||||

|

|

A Secondary lip type, pressure assisted, metal seat gives BI-DIRECTIONAL sealing once the PTFE seat burns away after the fire. |

Combination of seat and disc materials suitable up to 6000C (11120F) Seat Leakage Rate Class IV As per FCI 70-2. |